Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

High thixotropy + Low viscosity = Smooth injection, full filling, saving time and effort

In modern construction and structural retrofitting, the demand for high-performance anchoring solutions has never been greater. Whether reinforcing concrete structures, installing rebar in challenging orientations, or securing heavy-duty fixtures, contractors and engineers require adhesives that deliver consistent strength, ease of use, and reliability—regardless of working conditions.

Enter HM-500 Anchoring Epoxy—a next-generation structural adhesive engineered with cutting-edge nanomaterial technology to meet and exceed these expectations.

Advanced Nanomaterial Technology for Superior Performance

At the core of HM-500’s exceptional behavior lies its innovative nano-engineered formulation. By integrating advanced nanomaterials into the epoxy matrix, HM-500 forms a multi-dimensional network structure at the molecular level. This architecture not only enhances mechanical strength but also imparts outstanding thixotropic properties—the ability to become less viscous under shear stress (e.g., during injection) and rapidly regain viscosity once applied.

This unique balance enables HM-500 to maintain its shape and position immediately after dispensing, even in the most demanding orientations.

No Sagging. No Slipping. Total Control.

Thanks to its high thixotropy combined with low initial viscosity, HM-500 delivers unmatched application versatility:

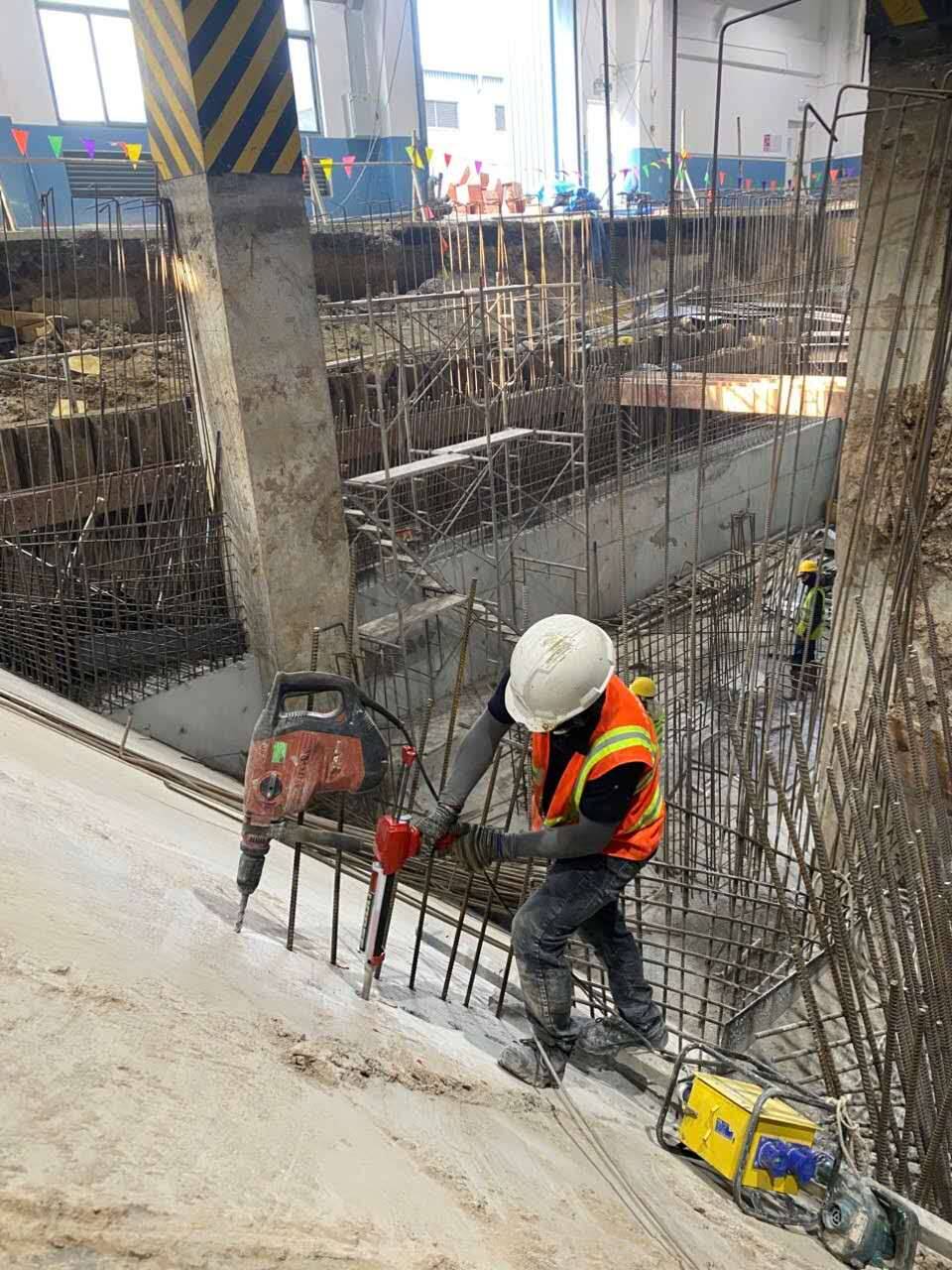

✅ Overhead injection? No sagging—even when applied to ceilings or inverted surfaces.

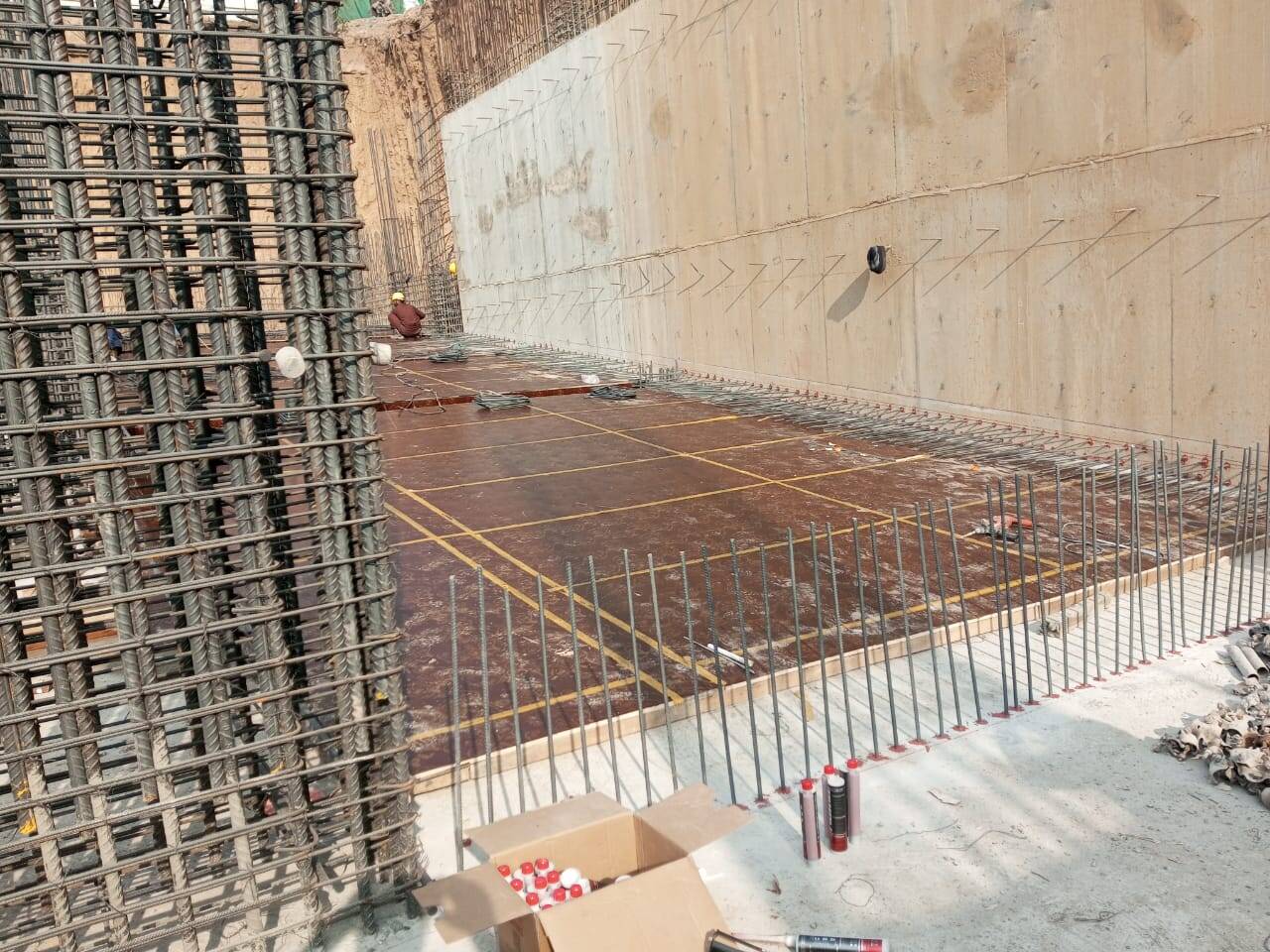

✅ Side-wall or vertical drilling? No slipping or slumping during curing.

✅ Deep or narrow holes? The low-viscosity phase ensures smooth flow and complete filling without air pockets or voids.

This eliminates the need for temporary supports, reduces material waste, and significantly cuts down on labor time—making HM-500 not just a technical upgrade, but a cost-effective solution for real-world job sites.

Optimized for Efficiency Without Compromising Strength

Unlike conventional epoxies that sacrifice workability for stability—or vice versa—HM-500 achieves the ideal synergy:

High thixotropy ensures positional stability post-application.

Low viscosity during injection allows effortless dispensing through standard cartridge guns or pump systems.

The result? Faster installation, consistent bond quality, and fewer reworks. Once cured, HM-500 develops exceptional bond strength with concrete, steel, and masonry, offering long-term durability against dynamic loads, moisture, and temperature fluctuations.

Trusted Across Applications

From seismic retrofitting and bridge rehabilitation to industrial equipment anchoring and high-rise construction, HM-500 has proven its reliability in diverse environments worldwide. Its performance remains consistent whether used indoors, outdoors, or in confined spaces—with no compromise on safety or structural integrity.

HM-500 Anchoring Epoxy: Where nanotechnology meets practical engineering.

Engineered for today’s challenges. Built for tomorrow’s standards.

Stable. Efficient. Unshakable.

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

two-components modified epoxy resin adhesive, with high quality plastic tube, double cartridge package